Good morning EUROAVIAns,

in today’s Fact Friday we conclude last week’s issue on the Venturi effect.

Let’s see how this notorious physical phenomena is applied for different fields!

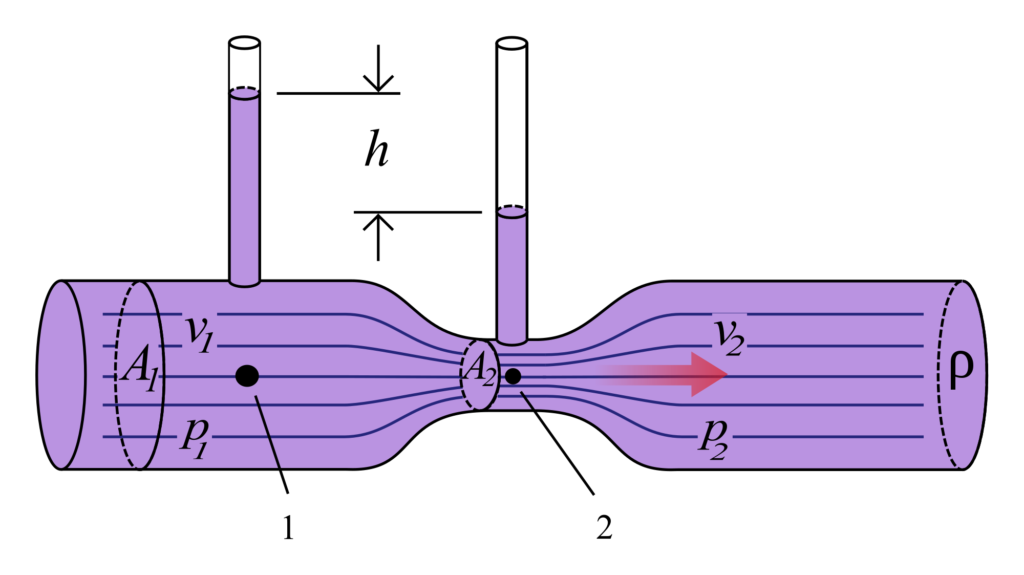

As you may know, pipes exploiting the Venturi effect are known as Venturi tubes. When used for metering purposes, they are also known as Venturi meters. Such instruments are usually deployed to determine the flow rate inside a pipe. By measuring the pressure at two different sections, the free section and choke, it is possible then to obtain the flow as geometry and fluid characteristics are known.

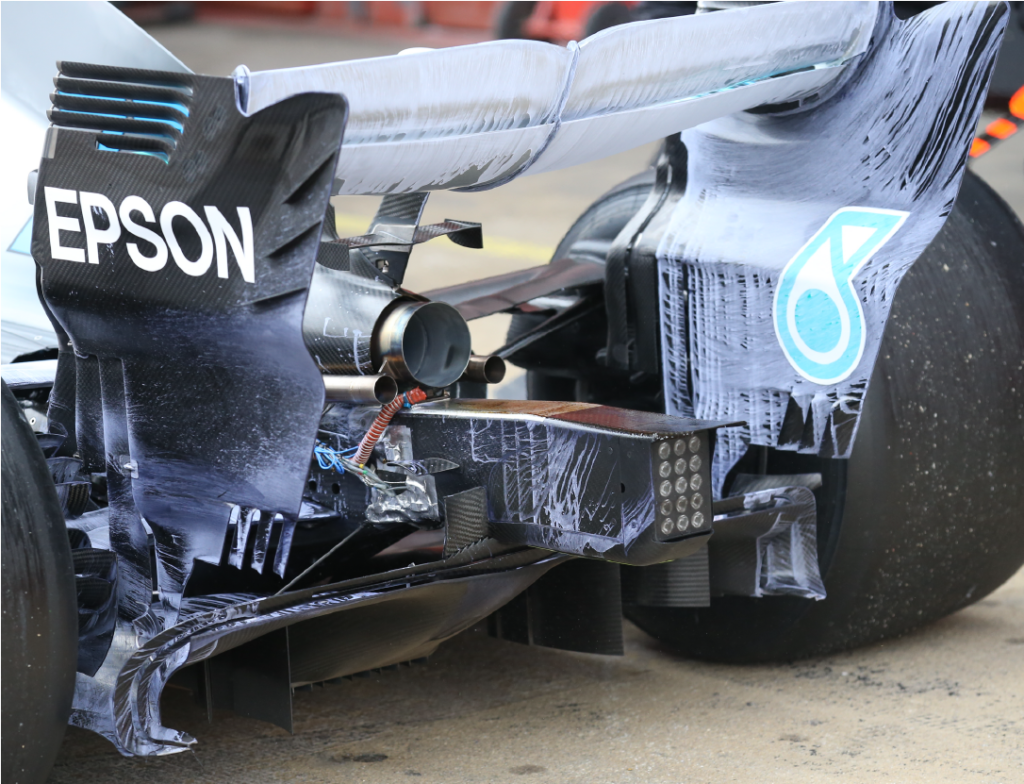

Venturi effect is largely utilised for aerodynamics race car performance increments. Devices which exploit this phenomena are diffuser. These components are part of the car underbody and improve the car’s aerodynamic properties by enhancing the transition between the high-velocity airflow underneath the car and the much slower freestream airflow of the ambient atmosphere. When a diffuser is used, the air flows into the underbody from the front of the car, accelerates and reduces pressure. At the transition of the flat bottom and diffuser is located a suction peak, where the lowest pressure is generated. Then, the diffuser eases this high velocity air back to freestream velocity, helping the underbody to be a more efficient downforce producing device by reducing the drag.

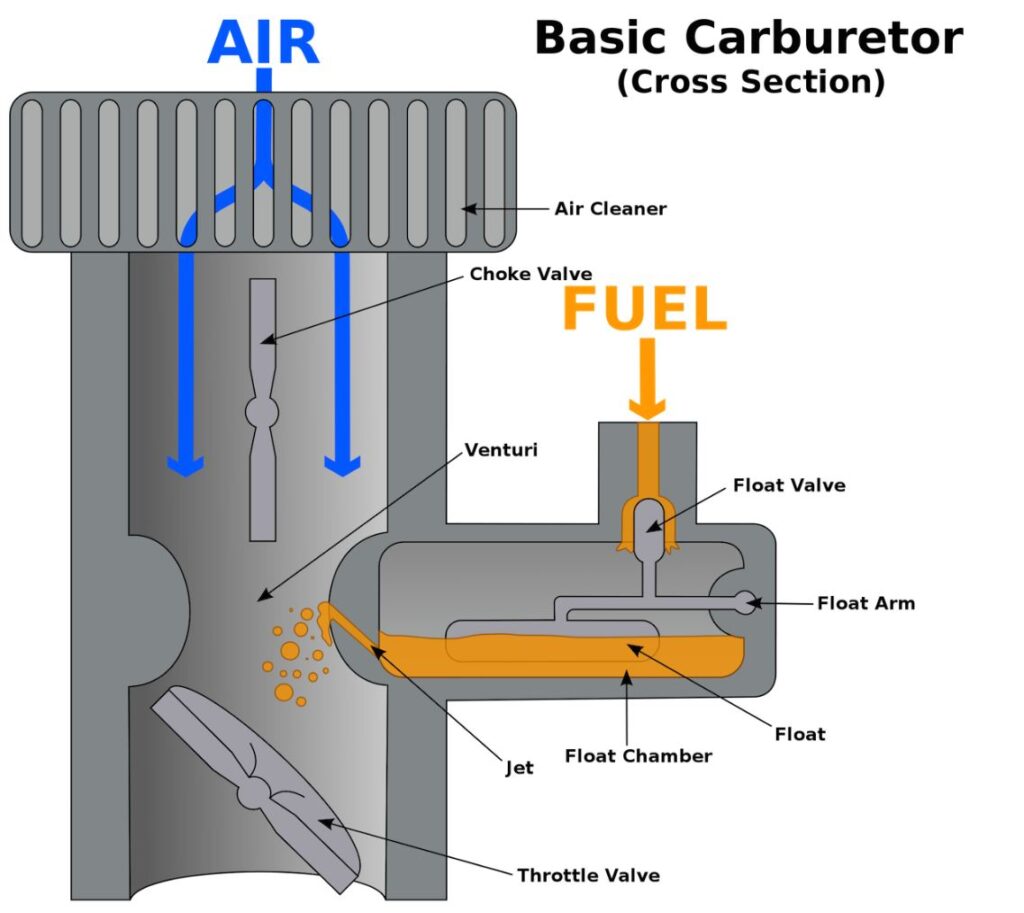

Application of Venturi effect is also used in carburetor, the device that mixes air and fuel for internal combustion engine in the proper air-fuel ratio for combustion. These components are usually built in a Venturi tube shape. Due to the effect, the air flowing through the constrictions increases its speed, lowering its pressure and suking therefore the fuel into the manifold, where it mixes with air.

Venturi effect can be also experienced over day-to-day life! Have you ever tried to place your thumb at the end of a garden hose? Or maybe, tried to empty a bottle of water faster?